Inspired vision comes from the top. As the design world spied its first glimpse of Nathan Allen’s Stator concept scooter, so did one of the world’s most prolific visionaries and entrepreneurs, Dr. Patrick Soon-Shiong. As Chairman and CEO of NantWorks, an ecosystem of companies aiming to create transformative global health information and next-generation pharma development network, Dr. Soon-Shiong’s passion for the Stator – and micromobility in general – lay in his belief that the potential impact on reducing carbon emissions through electric transportation in urban areas represents a smart future for us all, as well as a transformation in last mile access for all.

Dr. Soon-Shiong stood up a new NantWorks entity – NantMobility – to turn the Stator design concept into a practical last-mile transport vehicle, in sharp contrast to existing electric scooters that lack the stability, speed, and safety required for a daily commuter. In so doing, he chose seasoned development engineers from the NantWorks family with a track record of bringing complex products to market.

The NantMobility team, lifelong motorcycle and motorsports enthusiasts, selected ROBRADY as their design agent, based upon ROBRADY’s prior accomplishments in transportation design, engineering, fabrication and user experience. A track record in bringing innovative vehicles to market—including two wheeled platforms – made for a smart match with Stator. Starting with a DNA-level analysis, the studio launched a best-in-class, production-level design and development program – guided by reverence for the original concept.

From the ground up, the crowned oversized tires, inspired by lessons learned in moto GP racing, proved more than a match for rain and uneven terrain, while the revolutionary bladed wheels provide optimum cooling airflow for both the motor and brakes. An onboard charging system and user-friendly interface eliminated the need for a special charging station, adding momentum and freedom to support a premium-level micro-mobility lifestyle.

To realize Stator’s potential for an unmatched user experience, ROBRADY embraced the Stator team’s insistence on the use of unique and premium materials not found in common street scooters, including carbon fiber, repurposed exotic woods, and the latest technologies from the two wheel world. Leveraging supply chain relationships and an extensive history in powersports, engineers integrated carbon-fiber components and chromoly tubes for a lightweight, durable frame that could handle the abuse of a rugged urban terrain and still deliver a premium riding experience.

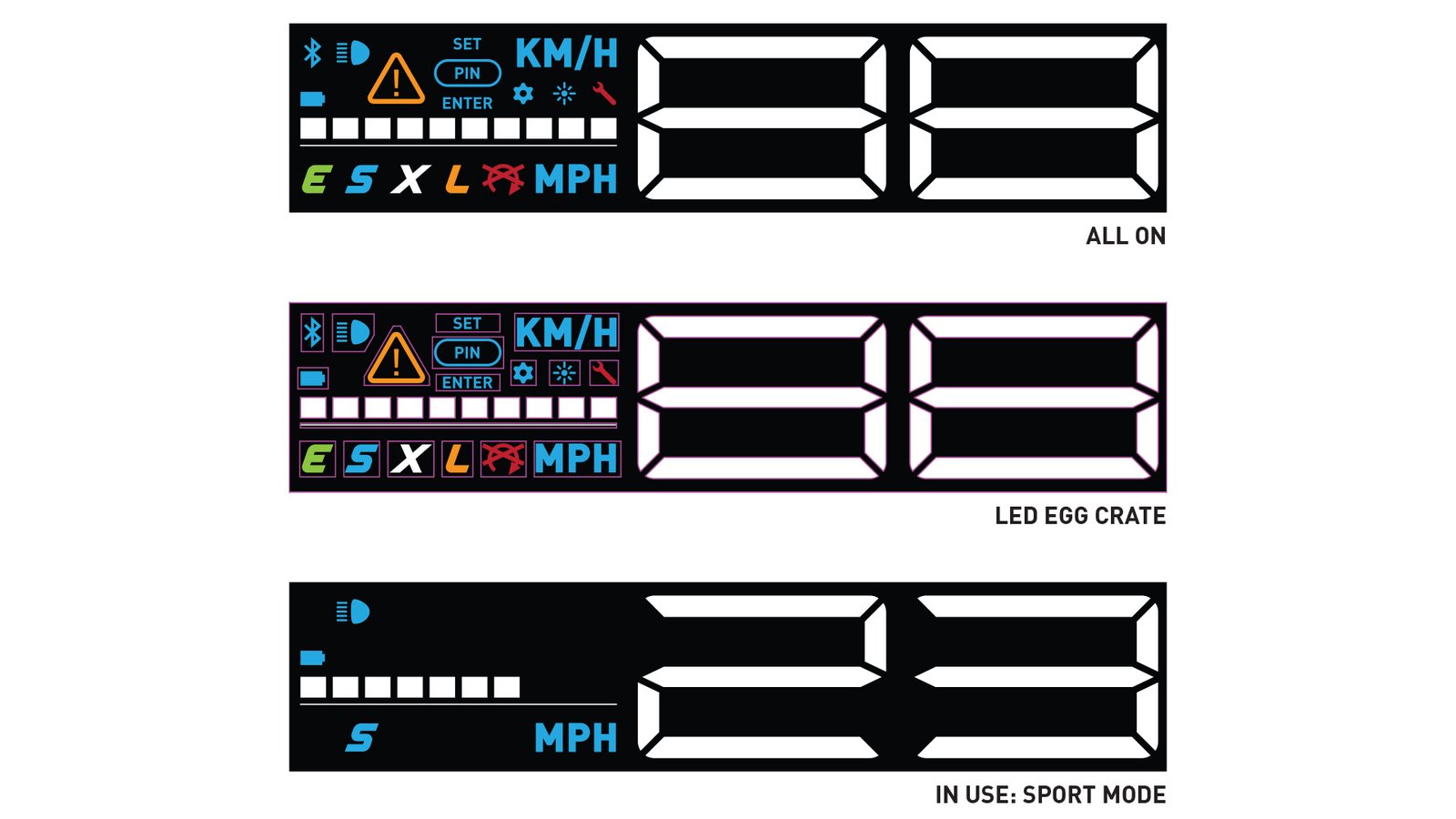

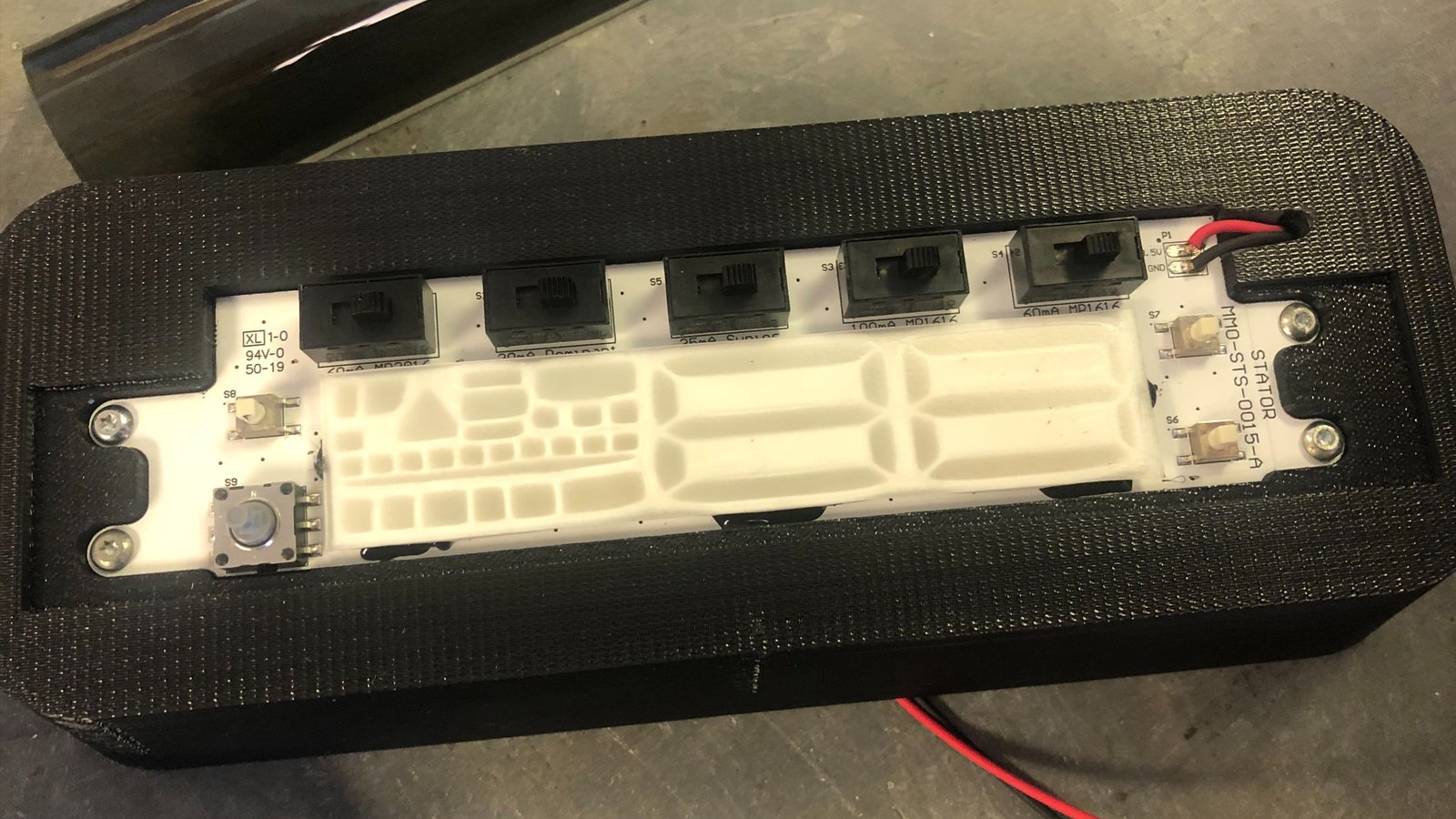

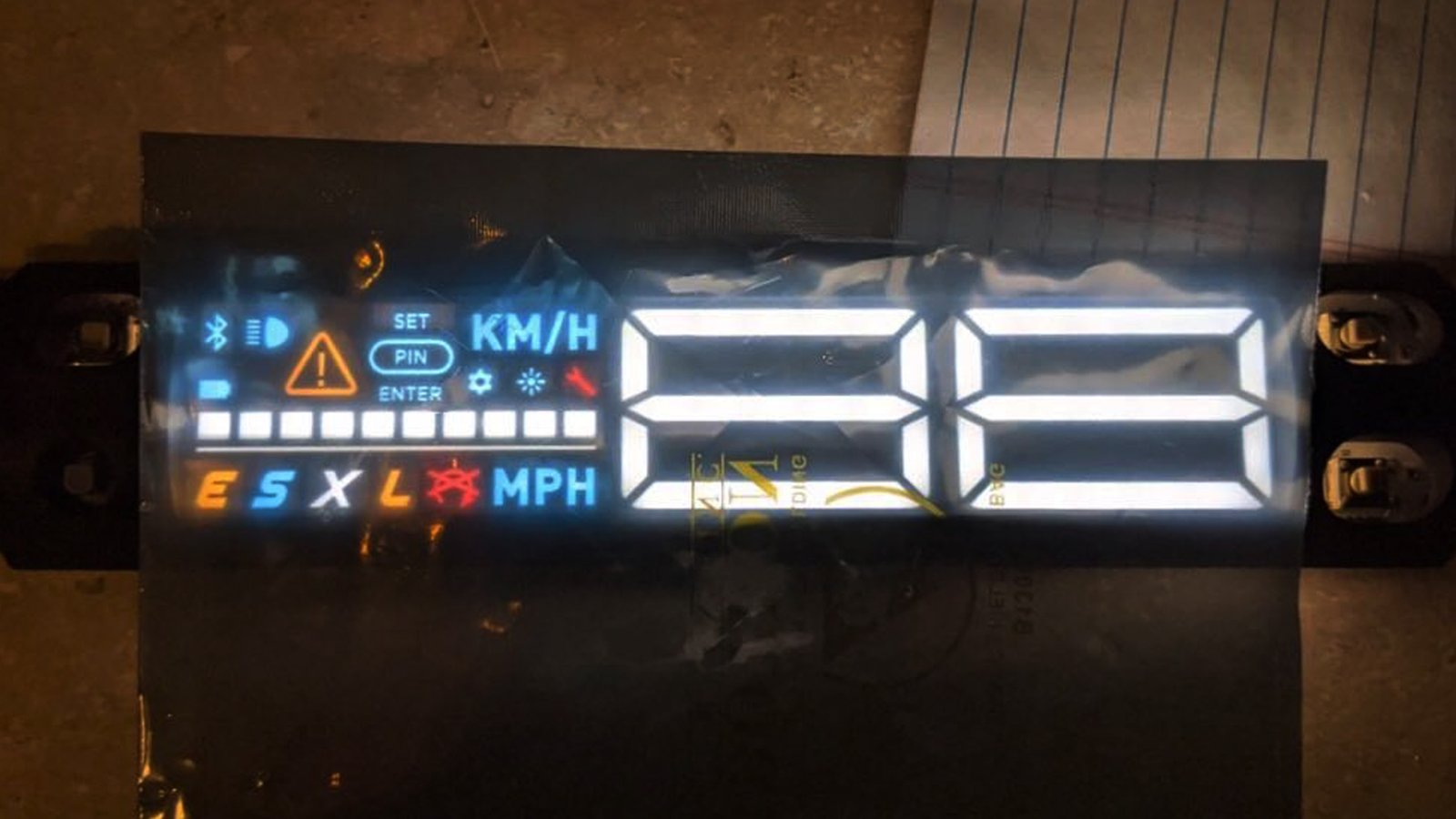

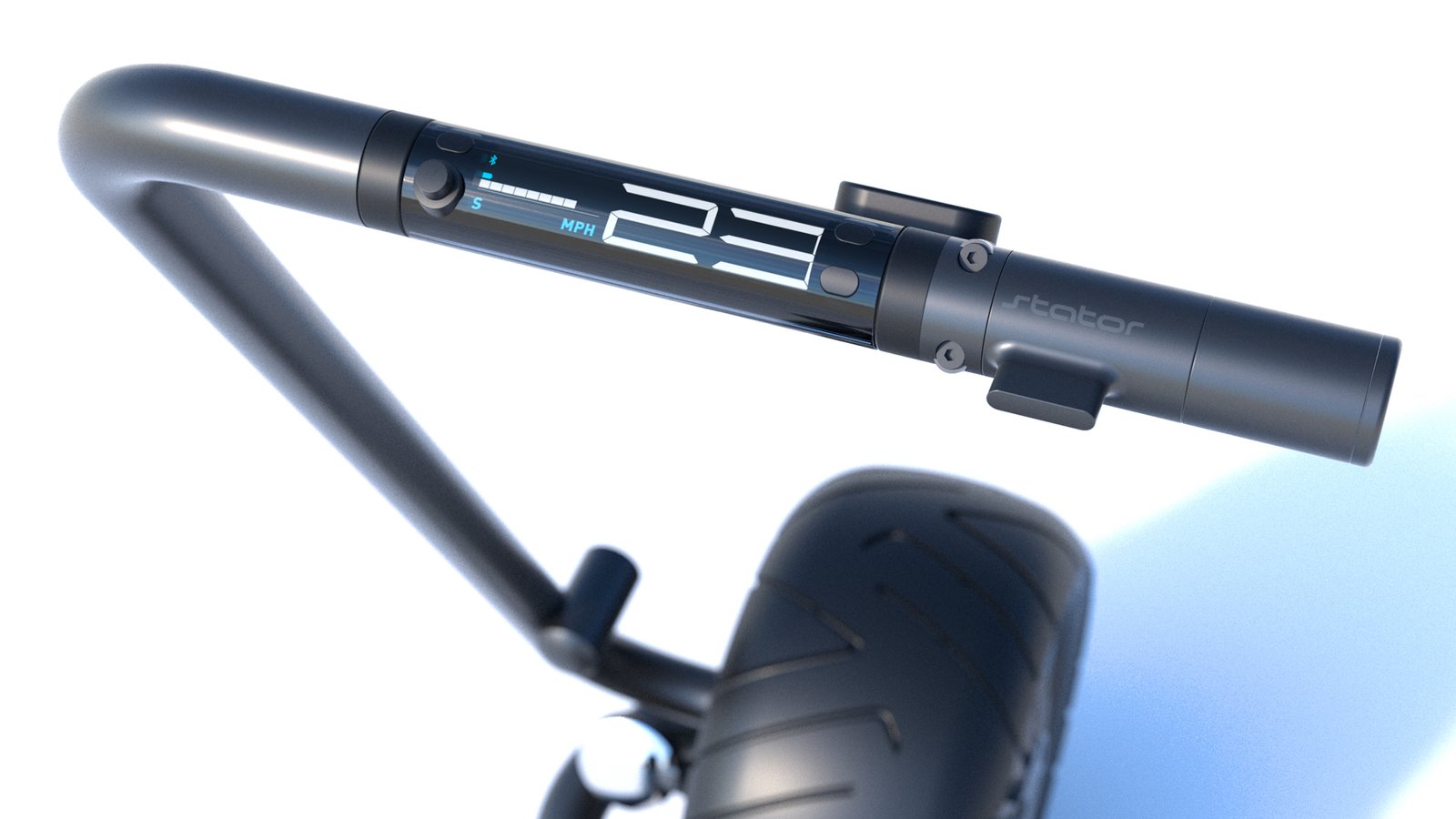

For controls and instrumentation on a vehicle of this caliber, ROBRADY drew on their wealth of technical and ergonomic know-how from designing performance vehicles to create a design-centric focal point. The highly engineered and visually compelling centerpiece sets the Stator’s user-interface apart as a bold element in the overall ride experience.

To further enhance a safe experience, ROBRADY engineers evolved from a single to dual caliper forward braking system in concert with a regenerative e-braking system to deliver smart, proportional, and dependable stopping power at any speed – via a single lever.

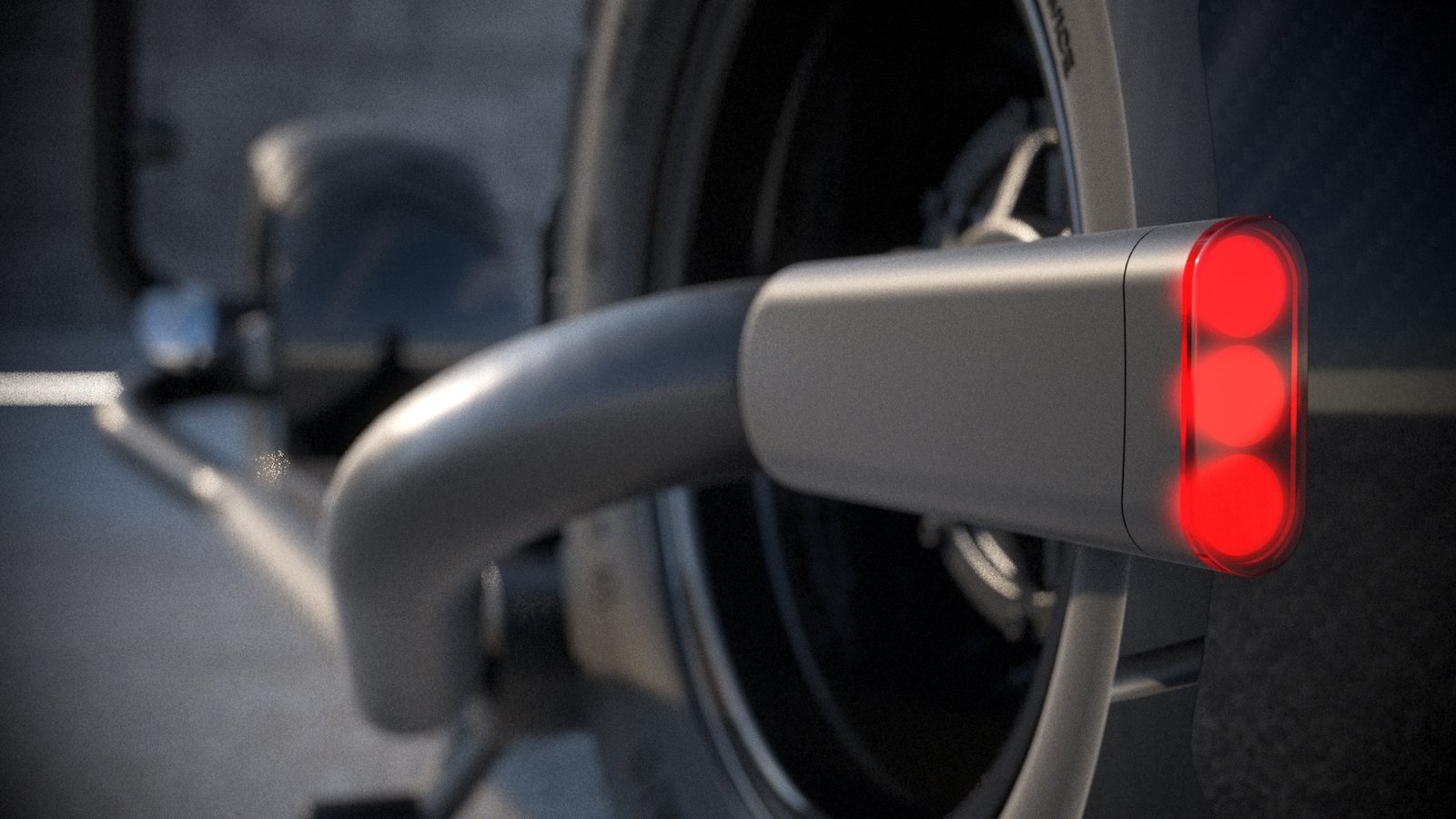

The solo ultrabright LED headlamp and equally sleek and effective rear brake light ensures safety, allowing riders to both see and be seen wherever they travel.

As easy on the eyes as it is the environment, the Stator electric scooter represents a significant advance in sustainable micromobility. ROBRADY is proud of its role in developing the iconic concept into a world-class riding experience—letting riders travel the world with more comfort, confidence, safety and style than ever before.

Electric Performance

The advanced electric performance capabilities paired with the innovative design of the Stator positions the eScooter in an elevated realm of performance and elegance. ROBRADY brought together a team of experts within the electric racing industry. Blake Fuller, championship racecar driver and lead battery engineer for the Stator project, developed the innovative lithium battery technology that is present in every IndyCar today.

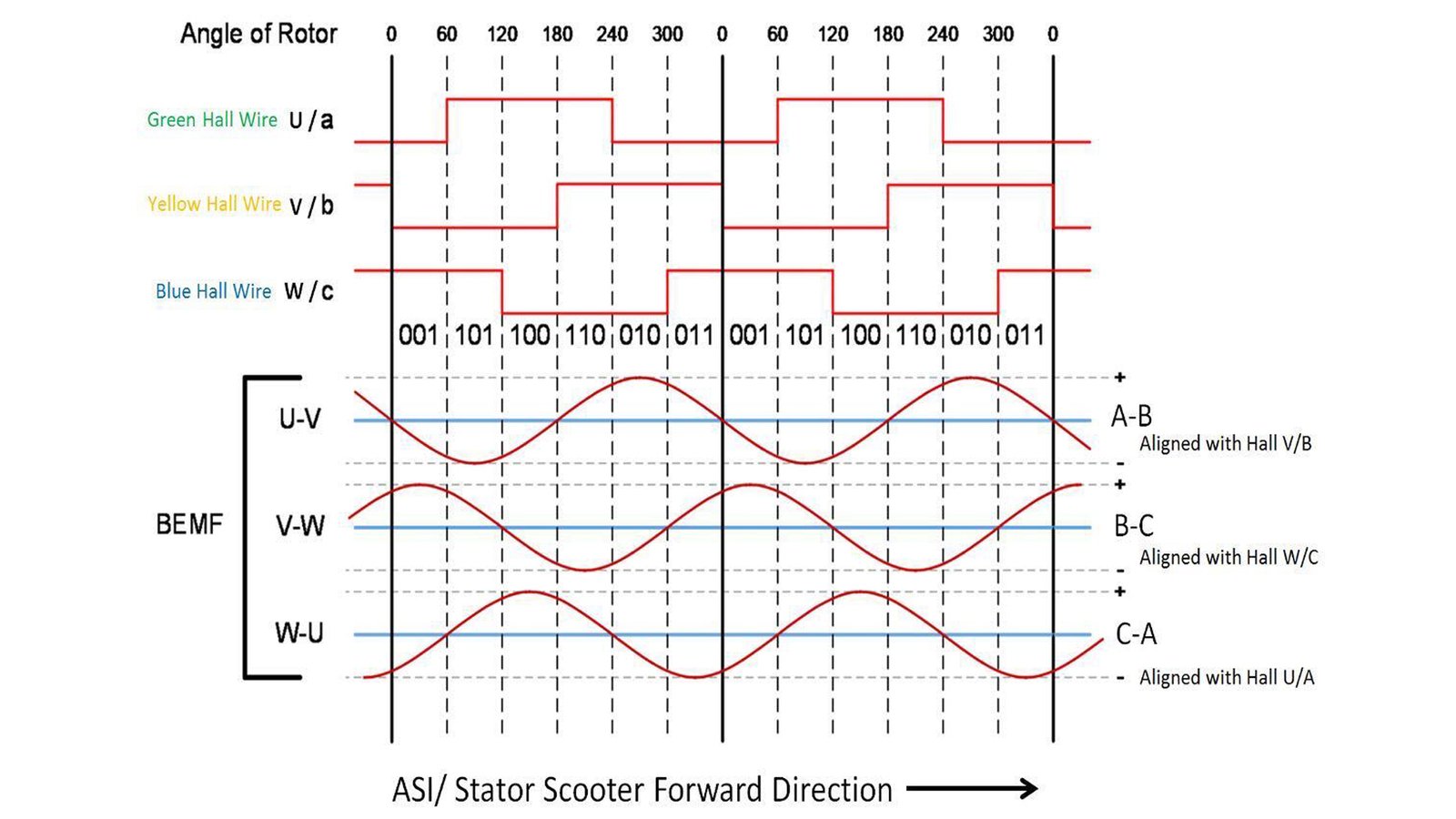

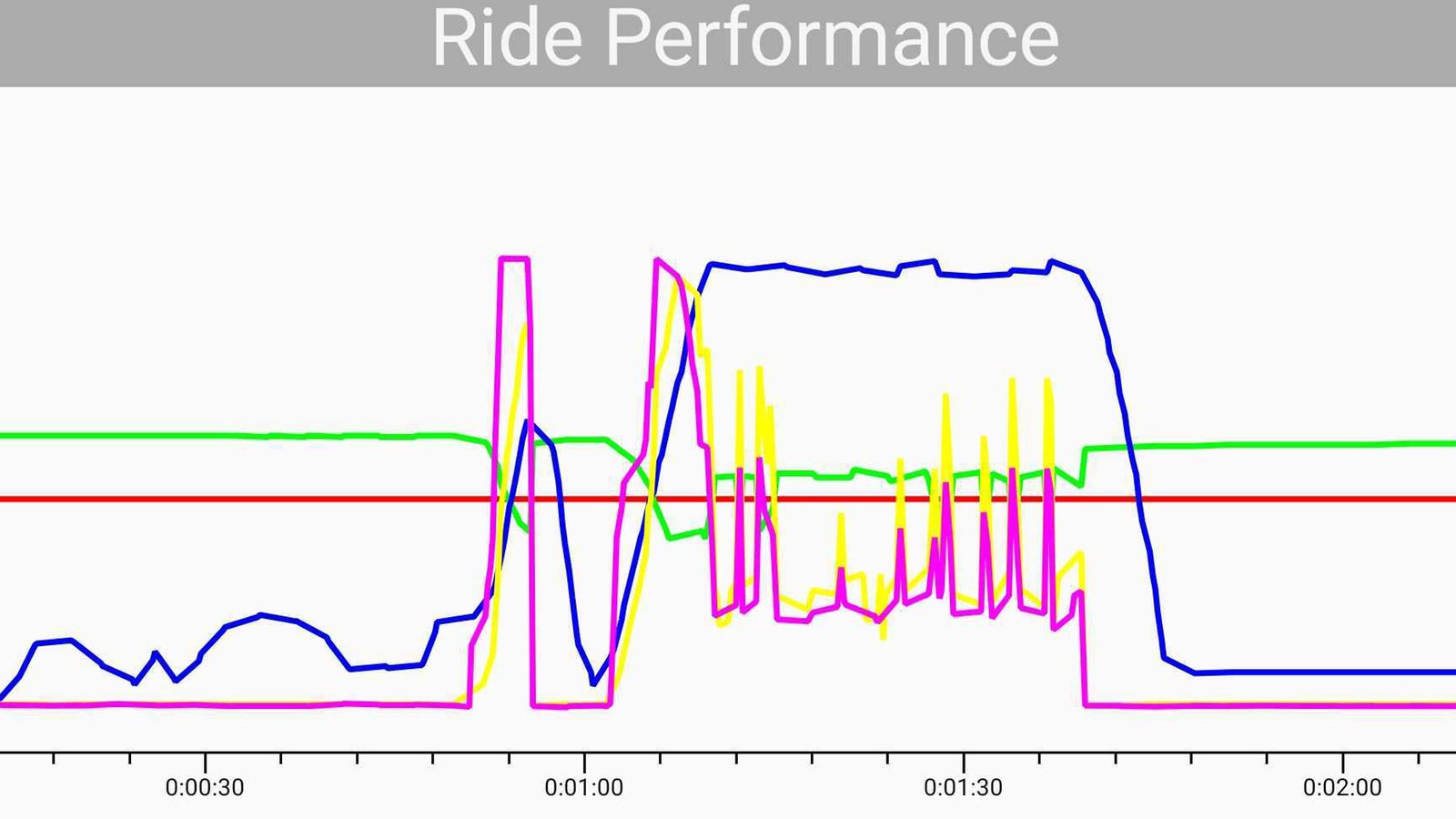

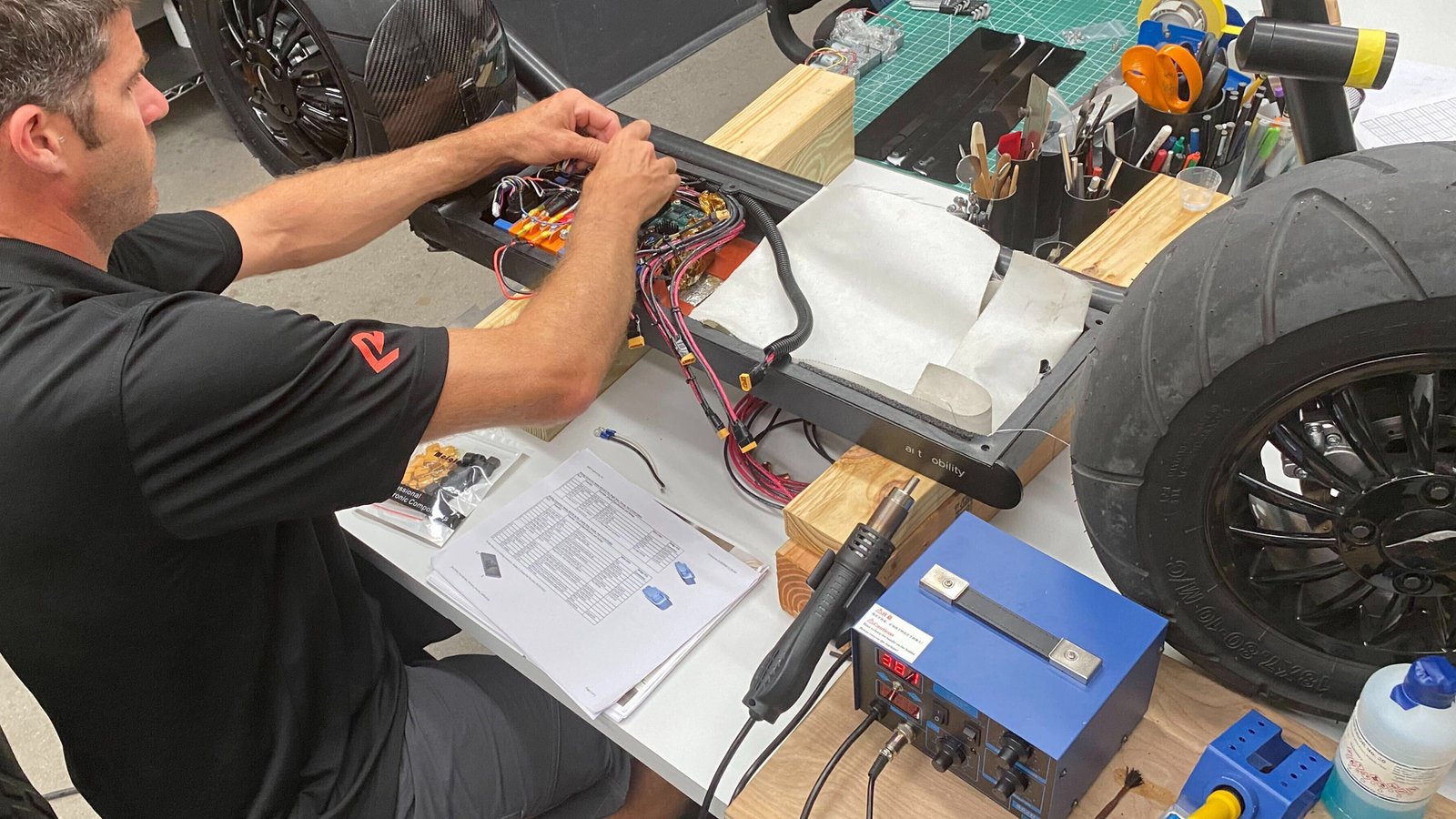

The sleek design of the Stator meant that all internal components had to be precisely oriented and calibrated to maintain the demanding performance requirements. ROBRADY collaborated with the extremely talented and experienced BGM Engineering team, as well as a handful of very select companies from around the world – ASI controllers and ETM direct drive motors – to refine production of the cutting-edge technology into component packaging, which allowed for both design and performance metrics to be harmoniously met. Custom testing fixtures, tools, and protocols specific to the Stator project validated and refined the results.

Industrial Design

User Interface / User Experience

Program Management

Because of the Stator team’s decades of product development experience, the ROBRADY team was afforded the luxury of focusing exclusively on product development, rather that expending valuable development time on the traditional tasks of traveling, reporting and presenting. The unflinching focus on comprehensive Program Management applied to every aspect of design, development, proto-fabrication, testing and production, reducing an otherwise customary two year development cycle to just over 10 months. From product requirements to resource allocation, we established clear objectives and deliverables, set sustainable timelines and effective metrics so our internal and external stakeholders are always well coordinated and focused on our mission to span from conceptual research to production reality.

The Stator stands as the pinnacle platform in micro-mobility, engendering high style, exhilarating performance, and unparalleled safety. To learn more about Stator visit www.stator.com